Production up to Width 410 mm

Press Line

Hardness up to F31 Temper

Profile Length up to 13.6 m

10” Billet

Alcas manufactures profiles up to 410 mm with our largest press, a 10” automatic press with a force of 4400 UST.

Our advanced technology press features the ‘Auto Large Quench’ system, allowing for the production

of homogeneously water quenched hardened aluminum profiles.

The 4400 UST press can produce various hardness levels using aluminum alloys such as EN AW 6060, 6061, 6063, 6463, 6005, and 6082, ranging from F13 to F31 temper hardness.

Thanks to our special aging oven, profiles can be aged up to 13.6 meters long.

Press Line

Production up to Width 310 mm

Hardness up to F31 Temper

Profile Length up to 13.6 m

8” Billet

We can produce up to 310 mm width profiles with our automatic 2750 UST extrusion press which uses 8” billets. Our advanced technology press features the ‘Auto Large Quench’ system, allowing the production of homogeneously water quenched hardened aluminum profiles.

In our 2750 UST press, we can produce profiles with various hardness levels using aluminum alloys such as EN AW 6060, 6061, 6063, 6463, 6005, and 6082, ranging from F13 to F31 temper hardness.

Thanks to our special again oven, profiles can be aged up to 13.6 meters long.

Press Line

Production up to 220 mm

Hardness up to F31 Temper

Profile Length up to 13.6 m

7” Billet

Our 1800 UST extrusion press is automatic type press using 7” billet and from 10 mm up to 220 mm width profiles can be produced.

The aluminum alloys like EN AW 6063, 6060, 6061, and 6463 can be used for production and also hard alloys like EN AW 6005 and 6082 can be hardened to F27 and F31 by quenching unit.

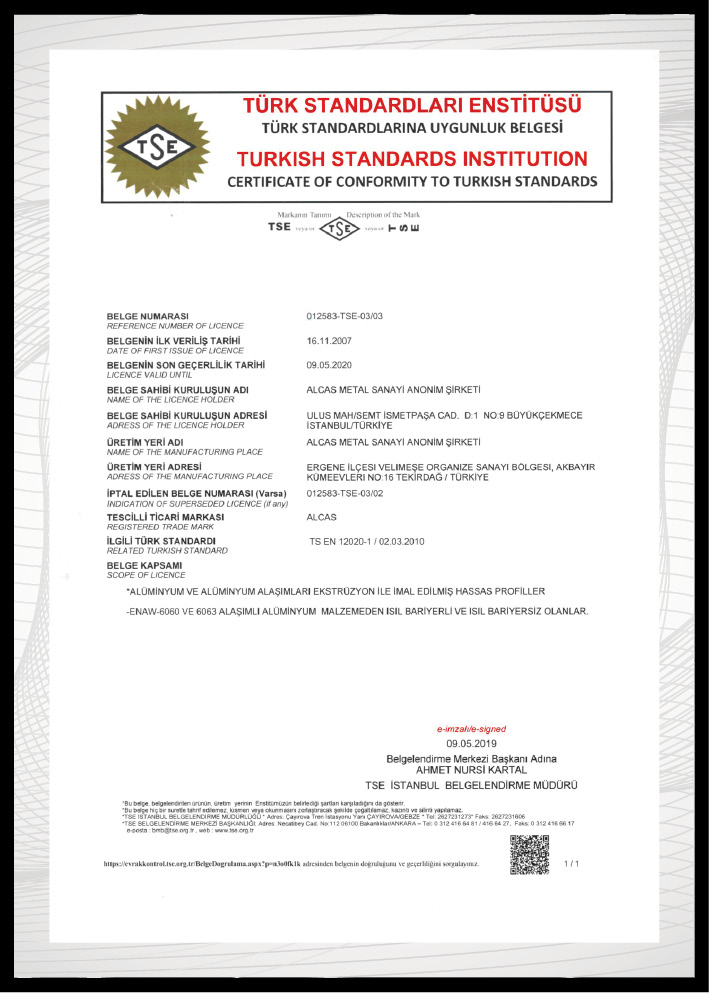

Our products are qualified to Euro norms EN 755-1 or EN 12020-1 due to customer demands. 13.6 meters length tempered profiles can be produced.

Press Line

Production up to 140 mm

Hardness up to F31 Temper

Profile Length up to 13.6 m

6” Billet

To increase our product diversity and produce thinner and smaller profiles, we commenced production with our 1540 UST press in 2015. In this line, profiles within the range of Width 30 mm to 140 mm are manufactured.

Our 3rd Extrusion Line is capable of highly efficient production, thanks to its 4 flow-controlled Rexroth hydraulic systems.

With advanced software, a proportional stretching system, a modern cooling system at the press output, and a robust forged body construction, this line is equipped to produce rigid alloys such

as EN AW 6082, EN AW 6061, EN AW 6005. It is well-suited for various industrial applications, including automotive, machinery, aviation, defense industry, and more

Press Line

Production up to 100 mm

Hardness up to F25 Temper

Profile Length up to 13.6 m

5” Billet

Our 900 UST press, which we commissioned in 2023, has started production for manufacturing thin and small-sized profiles ranging from 10 mm to 100 mm.

This line specializes in producing profiles with high precision and low gram weights. Our 5” Extrusion Line can achieve very rapid production thanks to four flowcontrolled Rexroth hydraulic systems.

Thanks to its advanced software, proportional tensioning system, and strong construction, with our 5” press, we can produce solid bars with a diameter of 5 mm or small profiles with a weight of 50-60 grams/m and a wall thickness of 0,8-1 mm with precise tolerances.